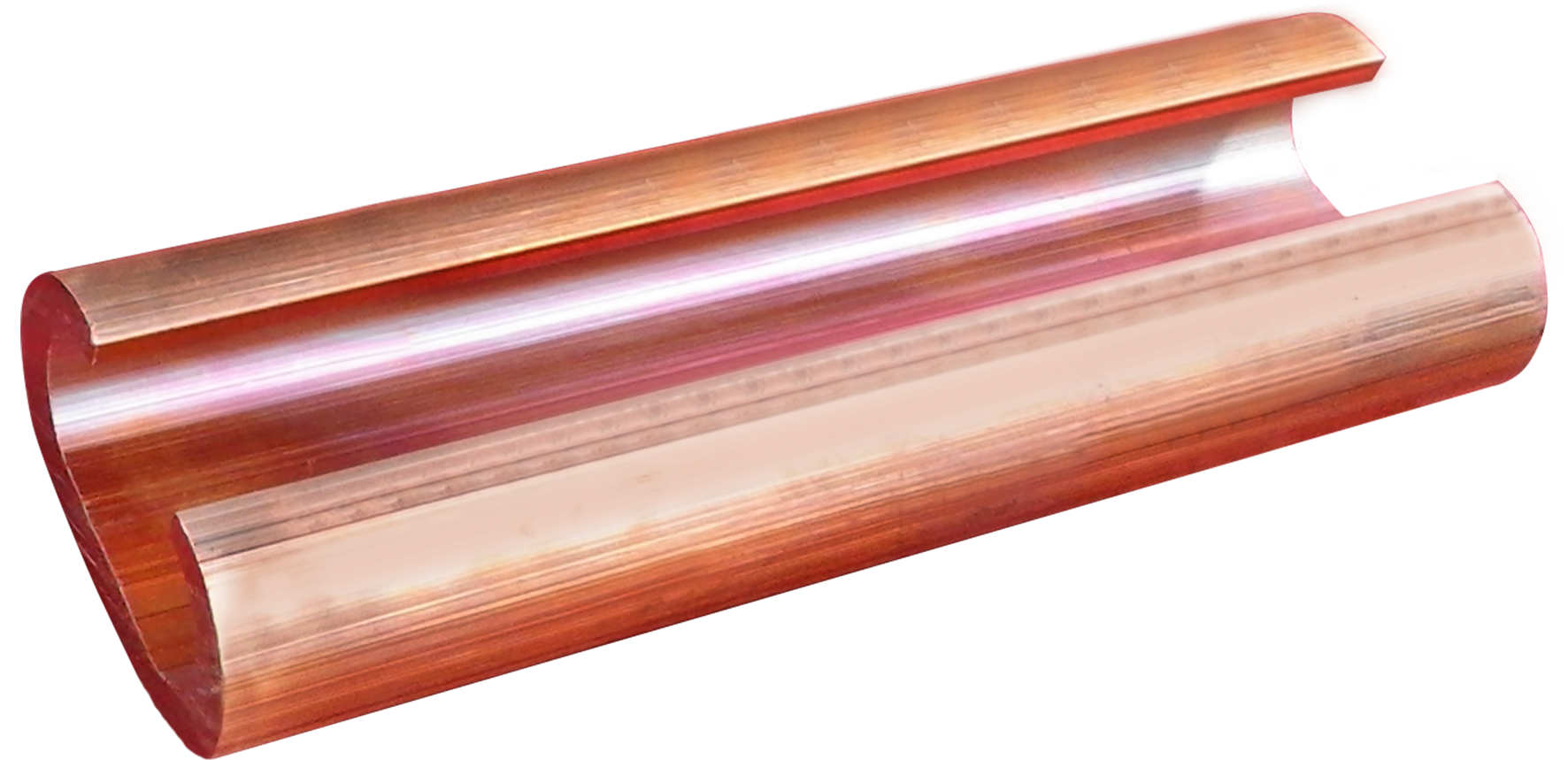

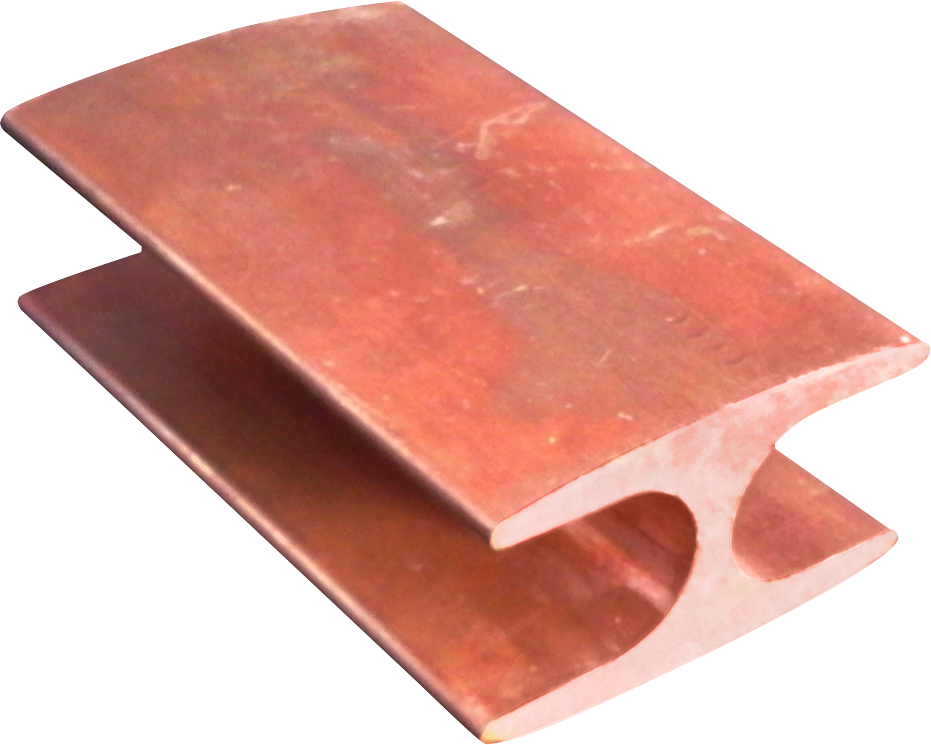

Busbar and shaped bars

Our copper and aluminum busbars possess such demanded characteristics as:

- structural versatility for easy installation and disassembly;

- excellent flexibility, allowing products to keep all useful characteristics in the deformed state;

- high melting point, guaranteeing a certain degree of fire safety at high loads and overloads;

- anti-corrosion;

- long service life.

The chemical composition of the copper busbars in%

| Сu | 99,99 | Pb | 0,00015 |

| Bi | 0,00006 | S | 0,0015 |

| Se | 0,00008 | Sn | 0,00008 |

| Те | 0,00010 | Ni | 0,00014 |

| Cr | 0,00005 | Fe | 0,0010 |

| Mn | 0,00062 | Si | 0,00037 |

| Sb | 0,00015 | Zn | 0,0036 |

| Cd | 0,00005 | Co | 0,00005 |

| As | 0,00005 | Ag | 0,0008 |

| Р | 0,00011 | O2 | <0,01 |

Mechanical properties

| Temporary tear resistance kgs/mm2 | 27,9 |

| Relative extension % | 6 |

| Electrical resistivity (at t=20oC) ohm mm2/m | 0.001-106 |

| Brinell hardness kgs/mm2 | 95 |

| Bending test (90°) | After bending there are no cracks and delaminations |

Busbar

We produce busbar from 2 to 6 meters in length:

| SIZE | a (mm) | b (mm) | WEIGHT (kg/m) |

| 12.5х12.5 | 12.5 | 12.5 | 1.391 |

| 15х6 | 6 | 15 | 0.801 |

| 20х3 | 3 | 20 | 0.534 |

| 20х4 | 4 | 20 | 0.712 |

| 20х5 | 5 | 20 | 0.890 |

| 20х8 | 8 | 20 | 1.424 |

| 22х3.8 | 3.8 | 22 | 0.744 |

| 25х2.5 | 2.5 | 25 | 0.556 |

| 25×3 | 3 | 25 | 0,667 |

| 25×8 | 8 | 25 | 1,780 |

| 30×3 | 3 | 30 | 0,801 |

| 30×4 | 4 | 30 | 1,068 |

| 30×6 | 6 | 30 | 1,602 |

| 30×7 | 7 | 30 | 1,869 |

| 30×8 | 8 | 30 | 2,136 |

| 30х10 | 10 | 30 | 2.670 |

| 30х20 | 20 | 30 | 5.340 |

| 31х3.5 | 3.5 | 31 | 0.966 |

| 31х7.5 | 7.5 | 31 | 2.069 |

| 32х4.1 | 4.1 | 32 | 1.168 |

| 35х2.44 | 2.44 | 35 | 0.760 |

| 35×3.5 | 3.5 | 35 | 1,246 |

| 35х4.4 | 4.4 | 35 | 1.371 |

| 40х3 | 3 | 40 | 1.068 |

| 40×4 | 4 | 40 | 1,424 |

| 40х4.5 | 4.5 | 40 | 1.602 |

| 40×5 | 5 | 40 | 1,780 |

| 40х6 | 6 | 40 | 2.136 |

| 40×8 | 8 | 40 | 2,849 |

| 40×10 | 10 | 40 | 3,560 |

| 40×12.5 | 12.5 | 40 | 4.450 |

| 40х20 | 20 | 40 | 7.120 |

| 50×3 | 3 | 50 | 1.335 |

| 50×5 | 5 | 50 | 2,225 |

| 50×6 | 6 | 50 | 2,670 |

| 50х8 | 8 | 50 | 3.560 |

| 50×10 | 10 | 50 | 4,450 |

| 60×4 | 4 | 60 | 2.136 |

| 60х5 | 5 | 60 | 2.670 |

| 60×6 | 6 | 60 | 3,204 |

| 60×8 | 8 | 60 | 4,272 |

| 60×10 | 10 | 60 | 5,340 |

| 60×16 | 16 | 60 | 8.544 |

| 61.5х6.5 | 6.5 | 61 | 3.558 |

| 65х4 | 4 | 65 | 2.314 |

| 70×5 | 5 | 70 | 3,115 |

| 70×5.5 | 5.5 | 70 | 3.426 |

| 70х10 | 10 | 70 | 6.230 |

| 71х5 | 5 | 71 | 3.159 |

| 80×8 | 8 | 80 | 5,696 |

| 80×10 | 10 | 80 | 7,120 |

| 80×20 | 20 | 80 | 14.240 |

| 90×10 | 10 | 90 | 8,010 |

| 100×10 | 10 | 100 | 8.900 |

| 120х10 | 10 | 120 | 10.680 |

| 120х12 | 12 | 120 | 12.816 |

| 120х20 | 20 | 120 | 21.360 |

| 140х15 | 15 | 140 | 18.690 |

| 150х10 | 10 | 150 | 13.350 |

| 160х15 | 15 | 160 | 21.360 |